Product description

E2001 SAINT GOBAIN PAM

For their operation the automatic control valves do not require additional energy. They are made from nodular (ductile) alloy with two-side epoxy protection of at least 250 microns, while the internal elements and links are made of stainless steel.

They can be used for the following:

- automatic ON / OFF operation,

- pressure control,

- flow control,

- level control,

- pressure relief / retaining,

- locking upon excessive flow rate,

- solving water bursts.

One valve can integrate several functions.

They are produced in nominal diameters between DN 50 and DN 700, pressure levels between PN 10 until PN 25.

For relative simple maintenance, they need not to be detached from the line.

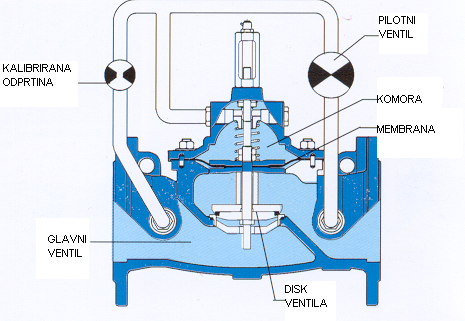

The main components of automatic control valves E 2001 are the valve body, pilot valve and intermediate pipe links.

The most important part of the valve for its typical operation is the chamber. The changes of the chamber volume enable various positions of the valve disk.

The pilot piping includes the TUP-93 multifunctional central control unit and one or several pilot valves by which the required pressure or flow can be adjusted. Both the main as well as pilot valves operate by way of hydraulic energy and thus ensure a completely autonomous operation ore reliability of the unit.

MAIN ADVANTAGES OF AUTOMATIC HYDRAULIC VALVES

1. Corrosion resistance

The pilot links and attachments are made of nickel coated stainless steel, bronze or brass.

2. Centering

The exact mechanical centering of the set cover - enclosure.

3. Anticavitation

Geometrical form of the valve seat and disk, which is replaceable, reduces the impact of cavitation.

4. Gradual opening

The conical cross section of the valve seat and mouth of the special QUAD-RING gasket enable gradual opening of the valve. When there is no flow the valve is sealed airtight.

5. Valve position indicator

Already in the standard version it is made of nickel coated brass. On the upper point it has an air release valve.

6. TUP-93 central controller consisting of:

- cleaning net,

- needle valve for controlling reaction speed,

- air valves for controlling the opening speed,

- air valves for the control of the opening speed.

7. Epoxy screen valve protection

The protective epoxy layer (of at least 250 microns) is applied to the valve after installation of the stainless steel parts (valve seat, centering ring,...).

8. Abrasion resistance

The valve seat and disk are already in the standard version made of stainless steel.

9. Special brackets for valve transportation

Special brackets for valve transportation are already integrated into the valve enclosure.

10. Manometer nozzle

A preinstalled manometer nozzle available.

OPTIONAL ELEMENTS

- Electric remote control

- Electric limit switch

- Analogue location transmitter 4-20mA: 24V CC (SPT type)

- Pilot valve with motor drive