Nodular cast iron is a high quality cast iron with added magnesium. It includes carbon in pure form as spheroidal graphite.

The nodular cast iron is therefore a material, which retains the good properties of the grey cast iron, this means castability (lower production cost) and features good mechanical properties, similar to steel, as for example high elasticity threshold and tensile strength and good notched impact strength. The nodular cast iron, which the manufacturer SAINT- GOBAIN PAM uses in the production of pipes features the following specifications:

- elastic limit: 270 do 300 N/mm2,

- tensile strength: 420 N/mm2,

- elongation: >10%.

Thanks to the good mechanical properties of the basic material, extensive range of tee elements and joining material, simple joining method and installation, the pipes made of nodular cast iron feature specific properties, recommended for water supply and sewage networks:

- enhanced hydraulic features,

- high operating pressure,

- high resistivity to corrosion due to good internal and external protection,

- high resistivity to external loads,

- high resistivity to seismic impact.

Safety factor

The mechanical tensions which the pipes during operation are subject to (pressure within the pipe and external impact) can be exactly anticipated. However, it is more difficult to anticipate all the loads the pipes are subject to across a longer period. The manufacturer SAINT- GOBAIN PAM has therefore selected for the pipes a very high safety factor and thus ensures a long life expectancy of the pipeline.

The wall thickness is dimensioned under consideration of the following safety factors:

- internal pressure:

- safety factor 2 regarding the elasticity threshold,

- the maximum permitted pressures can increase by 20 %.

- external pressure:

- safety factor 2 regarding damages,

- maximum vertical deformation is 3%.

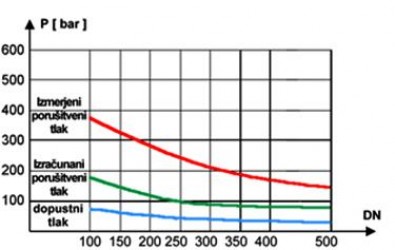

The measured breaking pressure exceeds the permitted operating pressure by more than twice. The safety factor varies depending on the pipe diameter.

Internal protection:

On the internal side, the pipes are protected by cement mortar, which includes between 60 and 70 % of slag. The cement coating is resistant against sulfates, which is contrary to Portland cement reacting chemically faster with water. The cement mortar is applied centrifugally, which allows a good grip on the surface, hardness and its smoothness. The smooth surface provides the pipes with excellent hydraulic properties, which due to the quality coating do not deteriorate with time. The low roughness factors of k = 0.1 mm (according to Colebrook) and actual larger net diameter compared to the nominal one ensure excellent hydraulic properties and low losses within the network.

External protection:

The pipes need to feature an adequate external corrosion protection, since they are laid into various aggressive ground. Depending on the area of installation (regarding the aggressiveness of the environment) the pipes feature on the external side various types of protection. In areas, where a higher corrosion level is expected it is recommended to perform resistivity measurements of the earth and a chemical analysis of the sample. Regarding the measurement results, the optimum external protection of the pipeline can be selected, namely:

| Resistivity [Ωcm] |

Earth corrosion level |

External protection pipes |

| < 500 | highly corrosive

|

STANDARD TT (passive protection)

|

| 500 - 1000 | corrosive

|

NATURAL |

| 1000 - 2000 | normal corrosive

|

NATURAL or STANDARD |

| 2000 - 10000 | low corrosive

|

NATURAL or STANDARD |

Types of joining pipes and tee elements

The pipes and tee fittings feature various shapes of joints, which ensure a 100 % sealing. The gaskets used for joining pipes and tee elements, have to provide water tightness during the complete operating period. Tests have shown that these requirements are met by the elastomeric rubber EPDM. When joining, the water tightness is achieved by a radial pressure of the gasket to the metal

MORE PRODUCTS

Sewerage and water discharge

Our range of activities include: technical design, distribution, installation, and maintenance of water-supply, sewage, and measuring/control systems with a 24-h technical support.